Fuel Guard Fuel Tank Security System

Compatible Vehicle Makes and Models for Construction Machinery Vehicles

What Do We Provide to Businesses as Fuel Guard

by Protecting Fuel Tanks in Construction Machinery Vehicles ?

Fuel Guard Protects Fuel Tanks in Construction Machinery Against Theft

Fuel tanks of construction machinery have very large volumes (300-500 LT). Our system guarantees that fuel, which is one of the biggest expense items of the business, is used only and only to "produce work". By zeroing out "invisible losses" caused by theft, it directly increases your profitability.

Fuel Guard Products Do Not Allow Fuel Loss and Keep Your Fleet Operation Seamless 24/7

A construction machine with an emptied tank cannot work that day. With Fuel Guard, there are no "no fuel" surprises when arriving at the construction site in the morning. Your machines start at the planned hour; delays and time losses caused by waiting for fuel replenishment in your projects end.

Fuel Guard Prevents Personnel Related Fuel Theft

It makes physically impossible not only thieves coming from outside but also personnel-related abuses (selling fuel, transferring to canisters, etc.) that can rarely occur. In this way, your honest employees are not left under unfair suspicion, and discussions within the business such as "where did the diesel go?" end, providing a fair and transparent working environment.

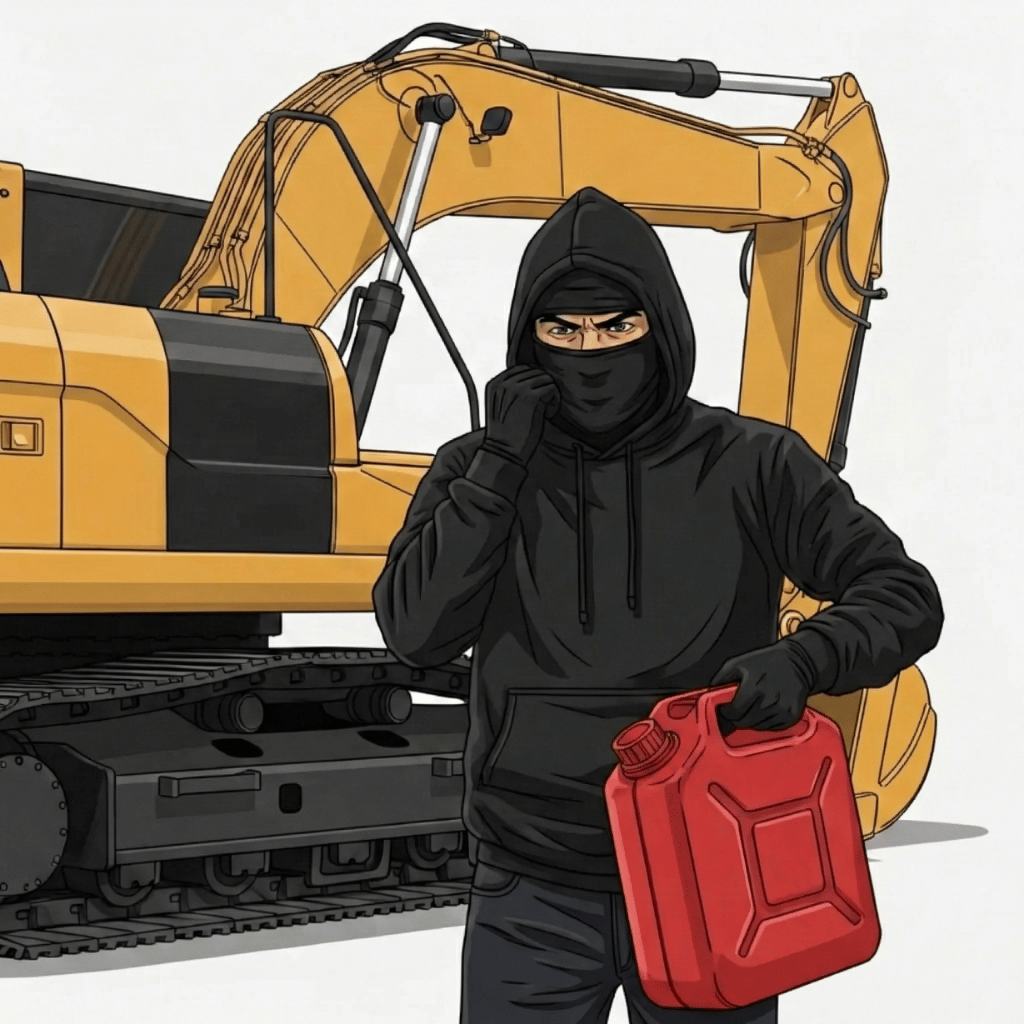

Fuel Guard Has a Wide Product Range That Ensures Fuel Thieves Give Up

Fuel Guard is a professional physical and visual barrier for thieves that is difficult to overcome. This deterrent ensures that the thief gives up without even attempting. By covering its purchase cost with even a single prevented theft attempt, the system pays for itself (amortizes) and starts earning money for the business.

Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank Fuel Thıeves Cannot Tamper wıth the Tank

Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel Fuel Thıeves Cannot Steal Fuel

Problems You May Experience If You Do Not Use Fuel Guard

Fuel Tank Protection Systems in Construction Machinery Vehicles ?

Fuel Theft Risk

Unprotected tanks are open targets for thefts carried out by the "siphoning" method. Hundreds of liters of fuel can be stolen in a single night, especially from construction machinery with high-volume tanks. This situation means a serious financial loss and loss of profit for your business every month that cannot be calculated.

Operational Disruption and Out of Service Status

A construction machine with an emptied tank cannot work when work starts in the morning. The machine remains idle until fuel replenishment is performed; the operator waits idle, and your project schedule is disrupted. The production loss during the hours the machine is not working is much more than the cost of the fuel.

Decrease in Labor and Performance Morale

During theft attempts, the tank neck can be forced, or while fuel is being withdrawn by primitive methods (dirty hoses, etc.), dust, soil, or sediment can escape into the tank. These foreign substances cause much higher service and repair bills than the fuel cost by damaging the sensitive injector and engine systems of construction machinery.

Fuel Guard Olarak

İş Makineleri Araçlarının Hangi Bölgelerde Mazotunu Koruyoruz

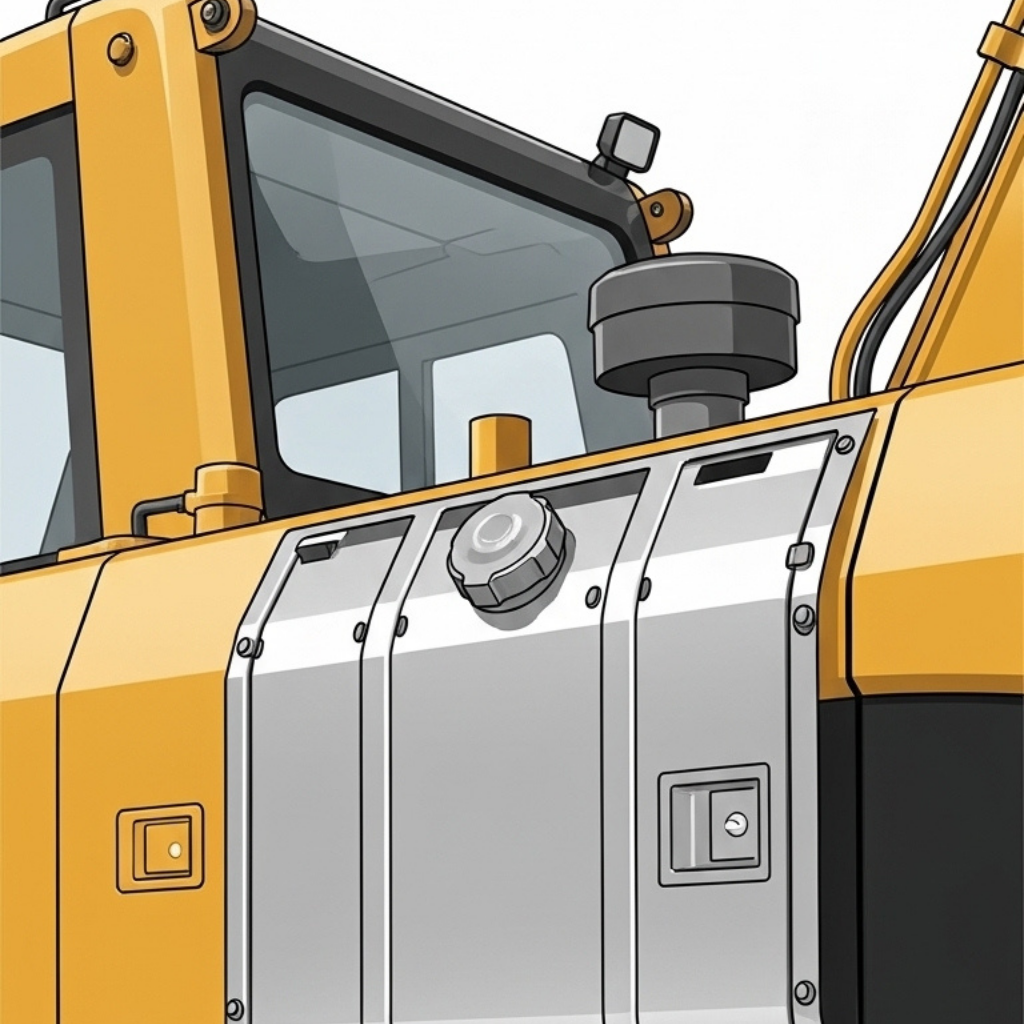

Tank Cap and Tank Neck (Anti-Siphon Protection)

The most common and first method that comes to mind in fuel theft is intervention through the fuel tank cap. Since the fuel tanks of construction machinery have very large volumes, forcing the caps, breaking them, or opening them with a duplicated key is a frequent occurrence. Fuel Guard protects this main entry point with high-security, patented locking systems and physical shields that show extraordinary resistance against external interventions such as lockpicks or crowbars.

However, Fuel Guard protection does not end here; the real deterrence begins inside the tank neck. At this point, "Anti-Siphon" (or "Siphon Preventive") technology comes into play. This special apparatus, permanently mounted to the tank neck, makes it physically impossible to drop a hose, pipe, or similar device into the tank and withdraw fuel by "siphoning." Even if the tank cap is somehow bypassed, the anti-siphon strainer prevents the thief from reaching the fuel. This is the first and strongest line of defense of Fuel Guard for construction equipment.

Fuel Float

When experienced fuel thieves realize that the tank cap is protected, they search for an alternative and weaker access point. In construction machinery tanks, this weak link is usually the fuel float area. This sensitive part, which measures the fuel level of the machine, is generally located at the top of the tank in a relatively less protected area and can be easily accessed due to its standard installation. By removing or breaking the float, thieves gain direct access to the inside of the tank and can quickly withdraw fuel from this point. Moreover, this intervention causes high repair and spare part costs for the business owner by damaging the float or the tank structure, in addition to the financial loss of the stolen fuel.

Anticipating this critical vulnerability, Fuel Guard offers steel protection covers and locking systems specially designed for the float area of heavy equipment. This secure cover is mounted over the float and completely seals this upper part of the tank against external interventions. Thus, even if the tank cap is secure with Anti-Siphon technology, theft attempts that can be made through the float area also result in failure.

Under-Tank Fuel Drain Plug

One of the methods often ignored in fuel security but with the most devastating results is draining from the bottom of the tank. Every fuel tank of construction machinery has a discharge plug placed for maintenance and cleaning purposes. Professional thieves, especially during overnight stays at construction sites or in unsecured parking areas, can get under the machine to unscrew this standard plug and drain the entire tank in a very short time. This method is one of the most difficult to detect and results in the highest amount of fuel loss.

To eliminate this extremely serious risk, Fuel Guard has developed special security solutions for the fuel tank discharge plugs of construction machinery. These solutions include locked plugs that replace the standard plug and are equipped with special keys, codes, or designs that make external intervention impossible. Some Fuel Guard models completely block access to this area by mounting an additional steel protection cover over the plug. In this way, the risk of fuel being "drained from the bottom" is reduced to zero, and the fuel tank is placed under a literal 360-degree protection.

Frequently Asked Questions for Fuel Tank Security in

Construction Machinery Vehicles ?

Is the Fuel Guard system compatible with every make and model of construction machinery ?

Yes. Fuel Guard systems are specially produced for the tank neck structures (threaded, lugged, bayonet) of all common construction machinery on the market such as CAT, JCB, Hitachi, Volvo, and Komatsu. Regardless of the brand or age of your machine, we definitely have a leak-proof solution that fits perfectly onto the tank neck.

Is any drilling or welding performed on the tank of the construction machine during installation ?

No, absolutely not. Our system is applied without damaging the original tank structure of the vehicle. Since it does not require cutting, drilling, or welding, it does not void the warranty of your construction machinery and does not decrease its second-hand value. The installation process is completed within minutes.

Can thieves withdraw fuel by inserting a thin hose or wire ?

No. The specially designed anti siphon (strainer) barriers within the system block any kind of hose, wire, or probing apparatus attempting to reach the bottom of the tank. While allowing fuel to enter, it makes it physically impossible to withdraw even a single drop out.

Is the product resistant to impacts and forcing with a crowbar ?

Yes. Construction machinery operates in harsh construction site conditions; therefore, our products are manufactured from high-strength metal alloys. It is resistant to rusting (corrosion). It provides superior physical resistance against attempts to break the tank cap, pry it open with a crowbar, or shatter it by impact.